Measuring your crew’s success and efficiency via studying on-site vs off-site time on the jobsite is an interesting method that can expose some interesting takeaways.

There are multiple angles to answering the question of “are we winning or not?”

At a basic level, and one you hear us talking about a lot, is simply measuring the estimated labor hours vs actual labor hours.

This one is super important, as if you are consistently going over estimated hours, it’s a drain on your profits.

But let’s say you are nailing it on estimated vs actual hours, consistently.

The next question is: how do we improve?

How do we become more efficient so we can do more jobs in the same amount of time?

Effectively increasing our production capacity, and increasing the revenue we can produce without increasing our costs.

A very helpful (and eye opening) thing to study is on-site vs off-site time.

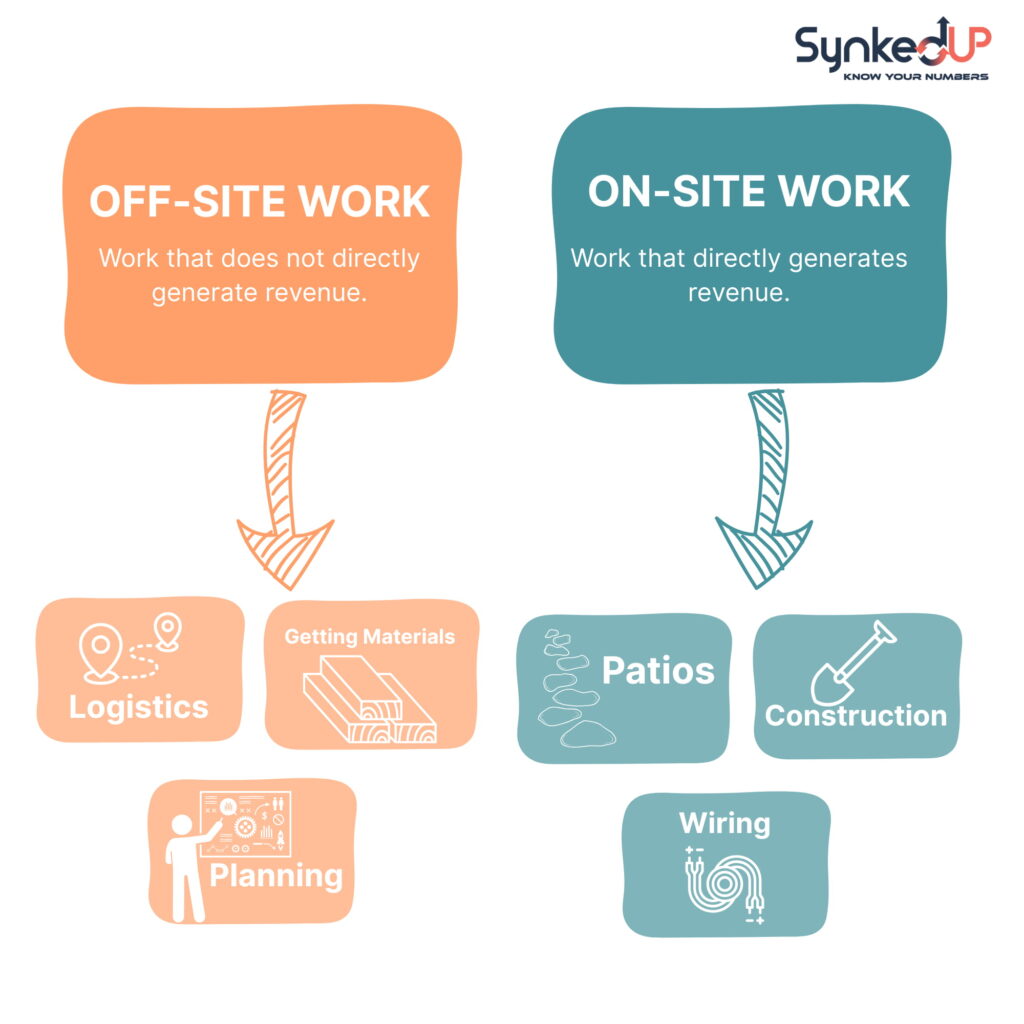

At it’s most basic premise, on-site time means revenue producing work is getting done.

Off-site time means the work itself is not getting done. Even though it may be needed tasks to enable the on-site work.

On-site work looks like the thing you actually sell getting completed. (Patios, plantings, construction, wiring, you fill in the blank)

Off-site work typically looks like logistics, getting materials, planning, etc.

At worst, off-site work can look like a bunch of your crew getting fuel at the local gas station and getting snacks.

At best, off-site work looks like legit planning, sourcing materials, and other necessary logistics.

But here’s the thing – there is often a lot of off-site work that does not need done by your skilled, well paid crew.

Your business makes money when your crew is getting work done on-site.

Your business does not make money when logistics are getting handled.

So the question is – what do you have your skilled crew doing, that someone else could do.

And by getting someone else to do it, your skilled crew’s time is freed up to do more on-site work, get more jobs done, and ultimately, produce more revenue in the same amount of time for the company.

An extreme example might be a doctor running to the supply room for more bandages, rather than assessing the patient and determining next steps.

A practical example might be your skilled crew lead cutting out of the jobsite early to make it to the supply yard before they close to get some more product for the next day.

A solution might look like getting that product delivered straight to the job site, cutting drive time for skilled crew members, and increasing the amount of on-site time, getting work done in their 8 hour day.

Yes, the delivery costs money.

But you know what costs more money?

Having your well paid crew running for logistics instead of getting actual on-site work done.

Your business makes money when the work gets done, it doesn’t care who does the logistics.

So the more you can maximize your skilled people’s time, the more work you can get done with the same people, the more revenue you can produce in the same amount of time.

We went through a phase of optimizing this when I worked at Tussey.

It looked like a relentless pursuit and study of “How do we get our crews to show up to work and get straight to the job site without any distractions?”

And “How do we keep them on the jobsite for as much of the workday as possible?”

Some practical outcomes of this were:

- We had a local kid fuel up all the trucks, check the oil, and clean out the trucks at the end of each day. (instead of the crew doing that)

- We had our supplier deliver product the crew needed the next day straight to the shop. It was closer to the supply yard, allowing for a cheap delivery, and prevented the need to leave the jobsite early to get product.

- We had bulk product stored at the shop, so the crew could get it on demand without running anywhere. (No more Lowes runs!)

The things that you would end up doing may be similar, may look different.

Ultimately the principle is: How do we reduce waste with our most expensive resource – skilled labor?

How do we maximize productivity with our most expensive resources?

And a very telling way of exposing those opportunities is to study on-site vs off-site time.

Hit me up with a reply, I’d like to hear what comes up for you when you reflect on the cause of the majority of your off-site time. And what you see as your biggest opportunity to maximize your production.

Cheers!

Weston Zimmerman

SynkedUP CEO & Founder

P.S. Get in the room with other business owners, and pick their brains on how they are optimizing for on-site time, in person, at our Contractor Summit event!

We’re going to be touring Evolve Design & Build’s facility, their office, their process, everything.

Sept 11-12, Kitty Hawk, NC. Right on the beach.

Get $250 off your tickets by using code EARLYBIRD, or if you are a SynkedUP user, get $300 off by using the code SYNKEDUP.

Want to see how SynkedUP helps contractors price their jobs profitably? Book a call.